Finding the path of least resistance: Aerodynamics in the age of electric vehicles

Have you ever wondered what clay, raindrops, and wind tunnels have in common? They all play pivotal roles in ensuring your Polestar is safe, energy-efficient, and exciting to drive. But that only scratches the surface. We talked with Anders Gunnarsson, Polestar’s Manager of Quality and Industrialisation Design Exterior, to learn more about the fascinating world of aerodynamics.

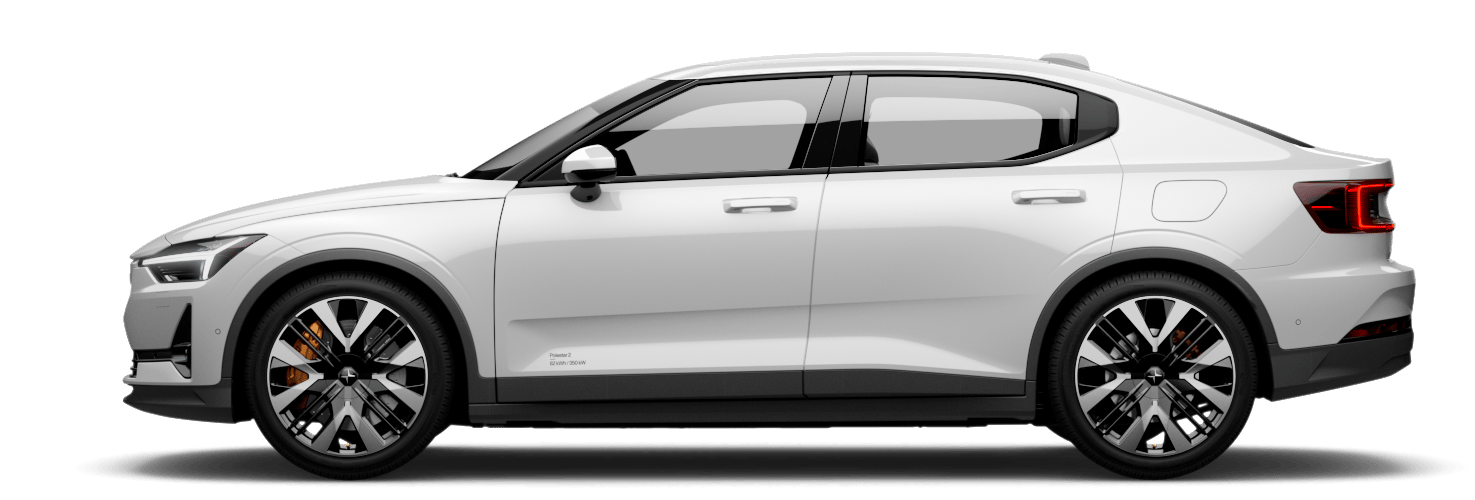

Aerodynamics is hugely important for any vehicle. How something moves through air can change how fast it can go and how much energy you need to move it forward. Polestar’s cars have all been designed with aerodynamics front of mind, giving them their distinct look, keeping range high, performance exciting, and a few things you might not have thought about.

Anders Gunnarsson knows the power of aerodynamics all too well: “It affects range - and top speed. It affects stability, noise, vibration, and harshness. It even keeps the car clean.” Yup, good aero can also keep gunk off your rearview camera. So, how does all this work?

Well, let’s get back to basics. Air isn’t an unknown - to get through it easily, you need to have a sleek, slippery shape. A frisbee will go further with less effort than a brick of the same mass, for example. That’s because air can flow more easily over a smooth disc than a jagged cuboid. But the perfect shape to get through air most efficiently? It might not be what you expect. Gunnarsson explains: “It's a waterdrop. It has to design itself to have the optimal shape.” A raindrop, being squishy and easily changeable, is formed as it falls, bending itself to ensure it cuts through air as easily as possible.

As it falls, air wraps around it perfectly, so there’s nothing to slow it down. If something’s sticking out at an odd angle, it’ll disturb the air and slow things down. Gunnarsson continues: “You don’t want to get separation of airflows. A water drop has one airflow wrapping from the front around its sides, and it falls easily. You want to have that on a car. You don’t want airflow to separate because that creates turbulence, which creates resistance, leading to noise and other unfavourable things.”

It's why the best shape for aerodynamicists is the teardrop, as opposed to, say, a very sharp, acicular object. In the basest terms: edgy things bad, smooth things good.

Here in lies the rub, however, as cars, unlike teardrops, can’t bend themselves to suit their conditions. They need to have headlights, space for passengers, a trunk, mirrors, and structures large enough to keep occupants safe in the event of an accident. They’re markedly more fixed than water.

Airflow and aesthetics usually go hand in hand

Back to the “digital” board

Before a vehicle becomes reality, design and engineering teams work to create a shape that can slice through air with ease, but also function as a car - whether it’s a sports car, coupé, sedan, SUV, or… anything.

It’s here that CFD (Computational Fluid Dynamics) come into play. When a car is at a stage where it’s ready to have its aero looked at, real-world models aren’t brought in straight away. Instead, digital models are created and run through virtual tests. “It’s something that came from testing. It’s part of the process. And it’s hugely important to understand how dynamics and design work together, otherwise it'd all be a bit ad hoc.”

In the virtual space, elements can be tweaked, tuned, and toyed with to get a car into the best possible shape. It’s a process that mixes engineering and design. “Something quite good for us as designers is that airflow and aesthetics usually go hand in hand,” Gunnarsson elaborates. But are there any surprises when a car goes in? Are the designers’ best intentions undone in a display of turbulent air? “You don't get too surprised, to be honest. We know what’s good and what is not good. It's more optimising.”

Into the wind tunnel

After refining a shape digitally, it’s time to put a physical version, often a clay model of the car, in a wind tunnel. You have seen wind tunnels on TV, in movies, or in documentaries. Essentially, it’s an environment that fires air from one end to the other, emulating how something moves in the real world. In these gigantic tubes, the various engineering and design teams can see how their new models will function out in the open.

By the time the car’s in there, it’s close to being finalised, but there’s still much to learn, says Gunnarsson. “If you have problems they appear in the wind tunnel. While we’re in there we can adjust small elements of the car. This happens almost all the way to sign-off. We’re talking a millimetre change sending off their flow in a different angle than before. If you're talking about a spoiler, how much should the flick be? We can adjust it and find out. We can add some clay and move some surfaces to see if they can improve. We fine-tune the aerodynamics of the vehicle. It’s a very, very, very important phase of development.”

It’s even about keeping the car clean

Real world innovations

It was time spent in the digital and real world that informed Gunnarsson and his team that removing the rear window on the Polestar 4 would work really well out on the road. With no rear glass to worry about, the team could bring the roofline of the car down to create a coupé shape, which in turn means air can flow more easily over the car. With CFD and the wind tunnel, the results of closing off the rear of the car were clear: Polestar 4 would have no rearview window. And, of course, as air can flow smoothly over the car, the rearview camera is kept clean - the dirt simply flies away from the lens.

Excellent aerodynamics can have a huge impact in the least likely ways, too. Gunnarsson gleefully explains: “There’s a pressure point on the windscreen that needs to be balanced so that when you use your windscreen wipers you don’t end up with a trail of water obscuring your view when you’re done. In the olden days, you always had this small water stream that ran up and onto the side window that could obscure your view of the wing mirrors. Get the aero right, and that’s not a problem anymore.” It’s not just keeping water out of sight but keeping batteries at the correct temperature, too. “Cooling is a big thing. Getting the right pressure in the right areas means air can be used to keep things where they should be.”

Many talk about aerodynamics as a performance aid only, but there’s way more to it than that. It’s because of Gunnarsson and his colleagues that Polestar can create innovative vehicles that work for everyone, take them a long way, and still be extremely fun to drive.

Words by: Alex Goy