Rethinking mobility with Re:Move

Sustainability is a unifying topic. One of the defining issues of the current age, the push for greater sustainability must span everything, every industry sector, every geography. Accordingly, it makes sense to collaborate. To unite those already engaged in the quest for a more sustainable future.

There's something really powerful about unexpected collaborations.

Design publication Wallpaper* has been trumpeting the merits of collaboration with their Handmade initiative for the past ten years, pairing designers, architects, and other creatives to make inspirational projects. Re-Made is their revitalised take on this premise. The idea of connecting creatives remains. The focus has shifted somewhat, to deal more directly with pressing social and environmental issues, creating projects that both foster discussion and demonstrate potential solutions.

Re:Move is one of those projects.

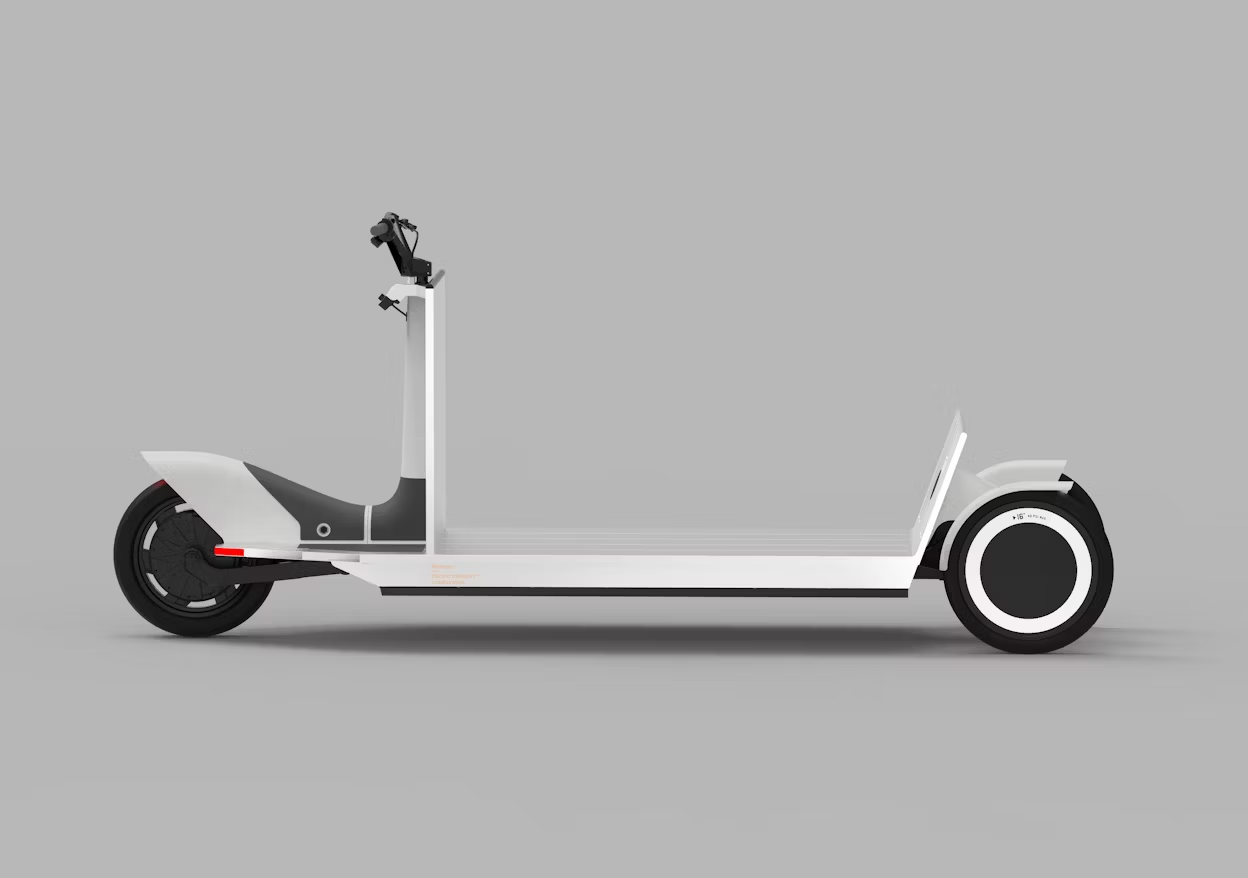

A small but multi-functional electric transporter, Re:Move exists to show a new take on electric mobility. A call from Wallpaper* Senior Editor Nick Compton to Industrial Designer Konstantin Grcic kickstarted the initiative. Norwegian aluminium firm Hydro entered the picture, providing both highly recyclable, lower carbon aluminium and an innovative construction method (more on that later) that unlocked new design opportunities for Grcic. CAKE provided an electric drivetrain optimised for three-wheeled mobility. And Polestar mobilised their Coventry-based R&D facility, combining the engineering expertise of Polestar Director of Design Engineering Chris Staunton with Corum Technology.

The goal was to maximise societal impact and minimise environmental impact. Flexibility was required from each of the participants. Which turned out to be crucial, as the project has seen no small number of tweaks. “This was really like a jam session,” opines Polestar CEO Thomas Ingenlath. “For one evening, everyone gets together and brings their instruments in order to play something unexpected.”

01/03

New use cases unfolded for Re:Move, from last-mile urban delivery vehicle to mobility solution for rural areas lacking established infrastructure. “The vehicle was conceived of as a cargo transporter for cities, first of all,” explains Grcic. “But it became quite clear during the project that rural areas with a different infrastructure could also be quite interesting.” The design of the vehicle went from an e-bike and trailer (made using friction stir welding, a technique pioneered by Hydro) to a single unit with a driver at the rear. “The project really started with this material from Hydro, which allowed us to build this very strong, lightweight platform,” Grcic says.

“We see the huge impact that our material choices have in terms of how a product will affect the climate,” says Polestar Head of Sustainability Fredrika Klarén. “I see more and more that we are so interconnected,” she continues. “We really need each other to fulfil our climate goals.”

Strong enough to transport substantial loads, yet narrow enough to make use of bike lanes, Re:Move encourages discussion about what e-mobility means in a variety of different settings, acting as both a symbol of, and a catalyst for, change. The vehicle will even make a virtual appearance in 2021’s South by Southwest festival.

Re:Move is yet to be completed. Tests are ongoing. Tweaks are occurring. New possibilities are being explored. And everyone involved shares the excitement and desire to see this dynamic electric sled complete the transition from idea to product.

“There’s something really powerful about unexpected collaborations,” says Compton. “I’ve been astounded by the generosity, and the time, energy and commitment people have offered.”