Journal 11.1

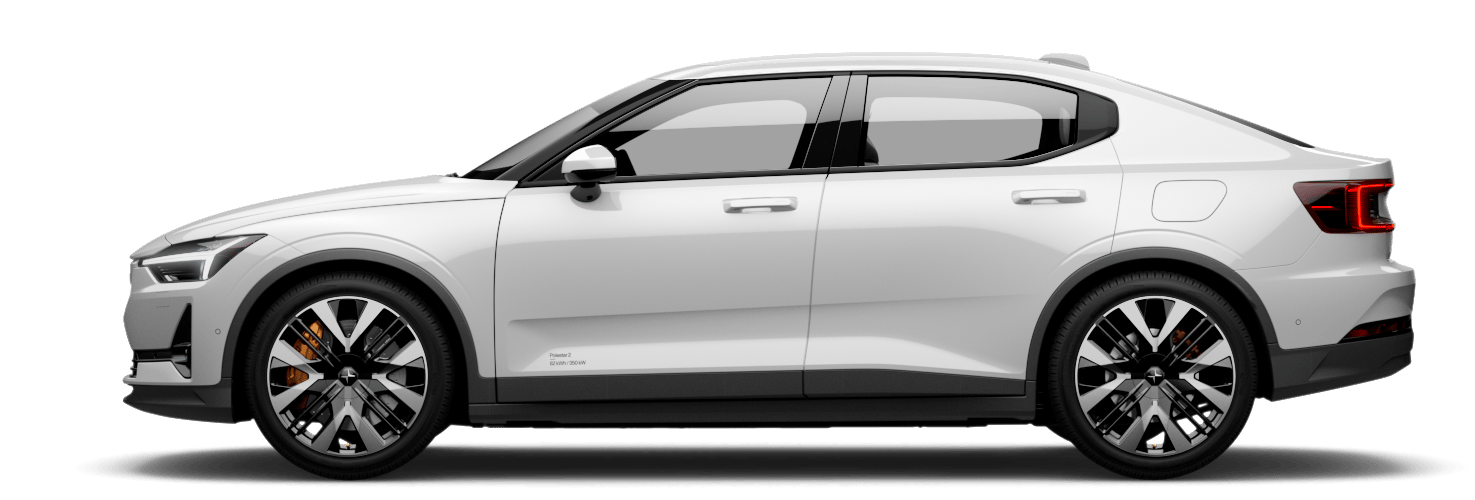

The Polestar 1 is tested in every conceivable condition and environment. These cars are optimized for snow, rain, blistering heat, arctic cold, and every road surface imaginable. The Polestar 1 will provide a peerless driver experience under any circumstances, and the testing process is designed to make that a certainty.

Crash Test

The Polestar 1 is tested in every conceivable condition and environment. These cars are optimized for snow, rain, blistering heat, arctic cold, and every road surface imaginable. The Polestar 1 will provide a peerless driver experience under any circumstances, and the testing process is designed to make that a certainty.

It’s not enough to only test for the predictable, however. It’s also imperative to test for the unpredictable. Accidents aren’t planned, but they can be planned for. And plan for them we do, by putting the verification prototype cars through crash tests at different speeds and various angles. It’s dramatic. It’s exhilarating. And it��’s necessary.