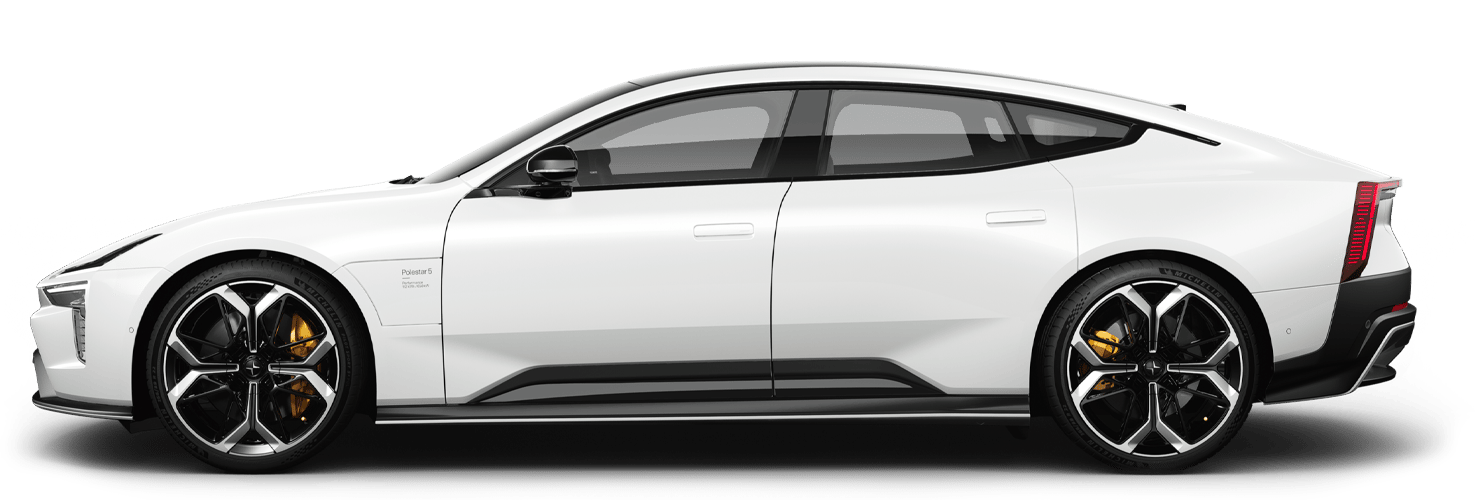

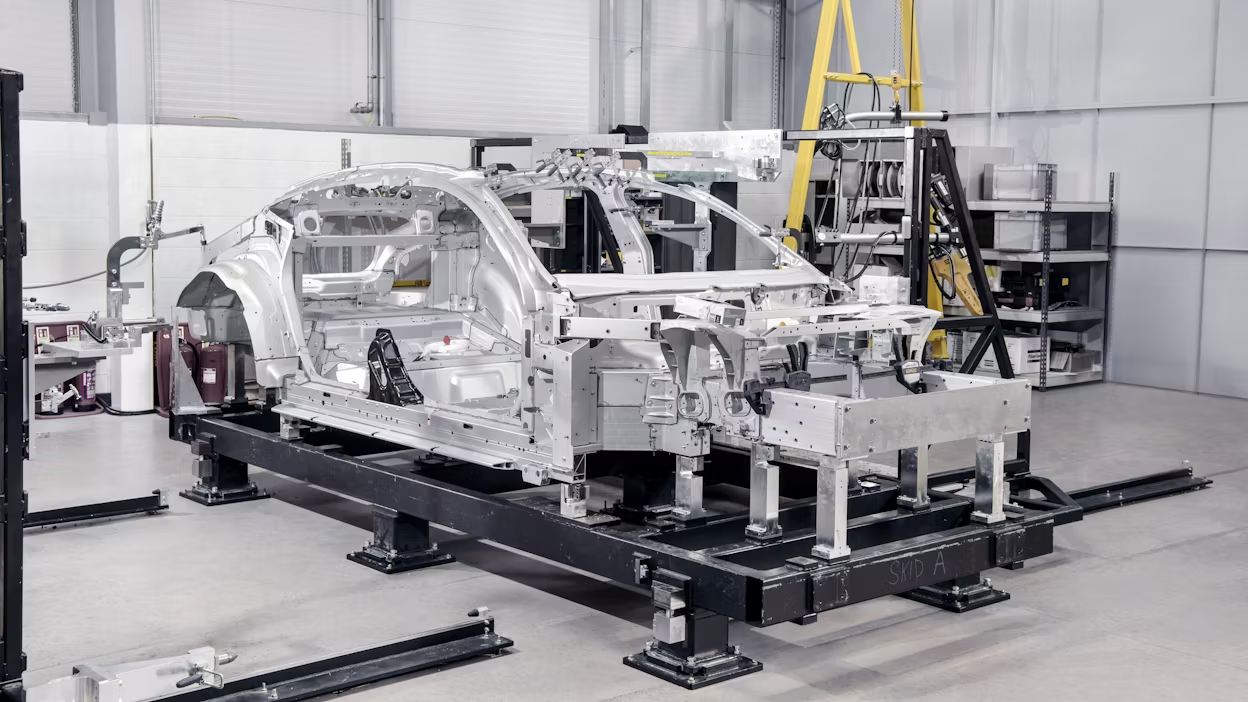

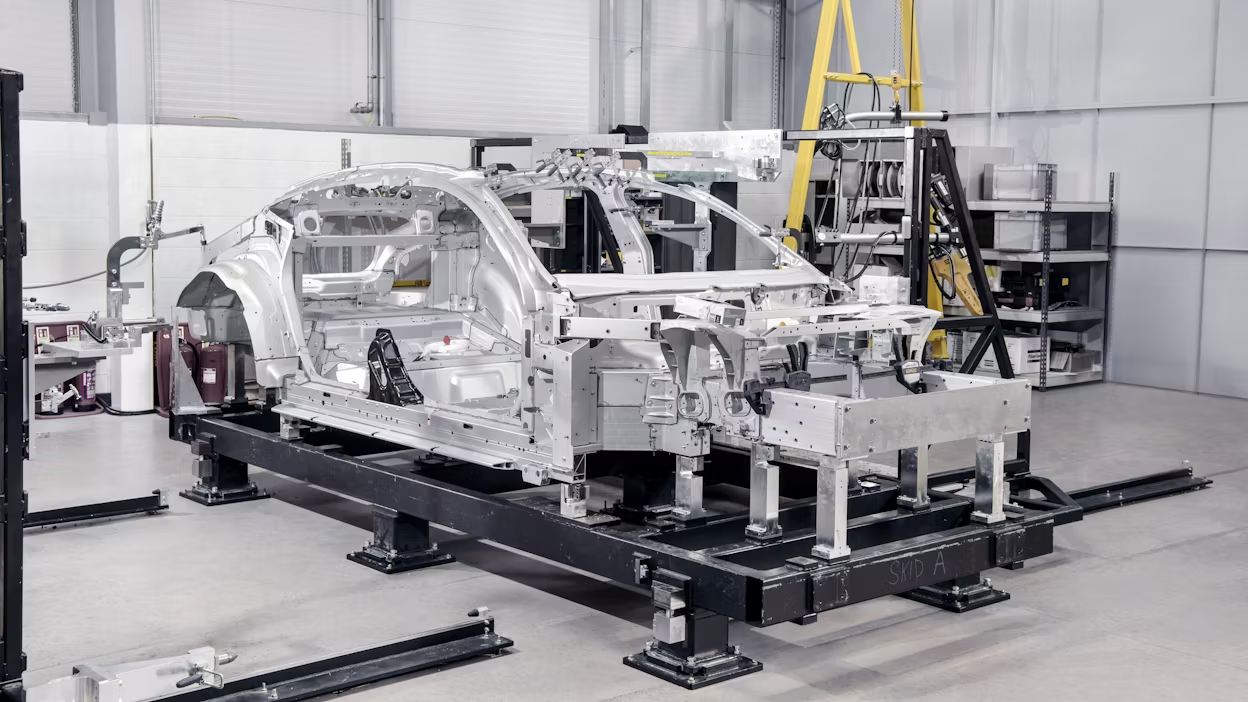

Precious metal: the bonded aluminium unibody of Polestar 5

Aluminium doesn’t get enough credit. Yes, it sees widespread use in a variety of everyday items like cans, siding, and utensils. It may technically be a common metal, but it’s plenty precious to us. Not least because it’s lightweight, rigid, and highly recyclable. Especially when it’s bonded. Like in the case of Polestar 5.

We knew we wanted this car to be lightweight, we knew we wanted high quality and we knew we wanted it quickly.

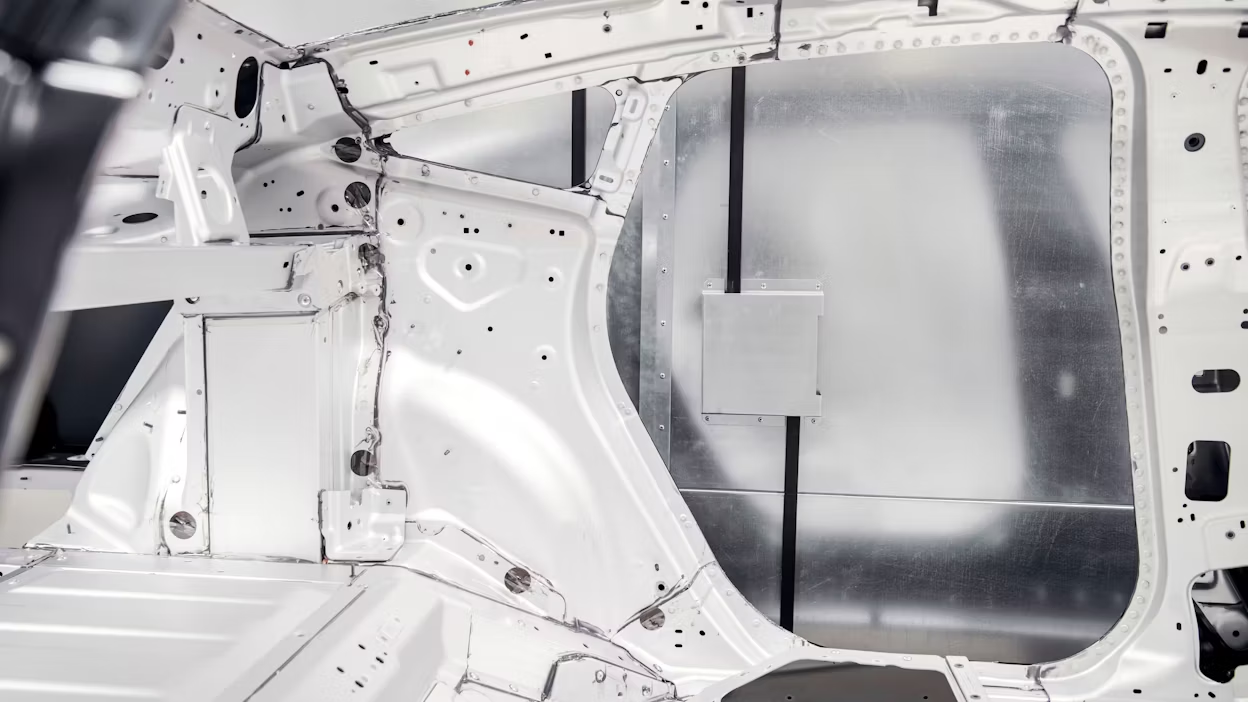

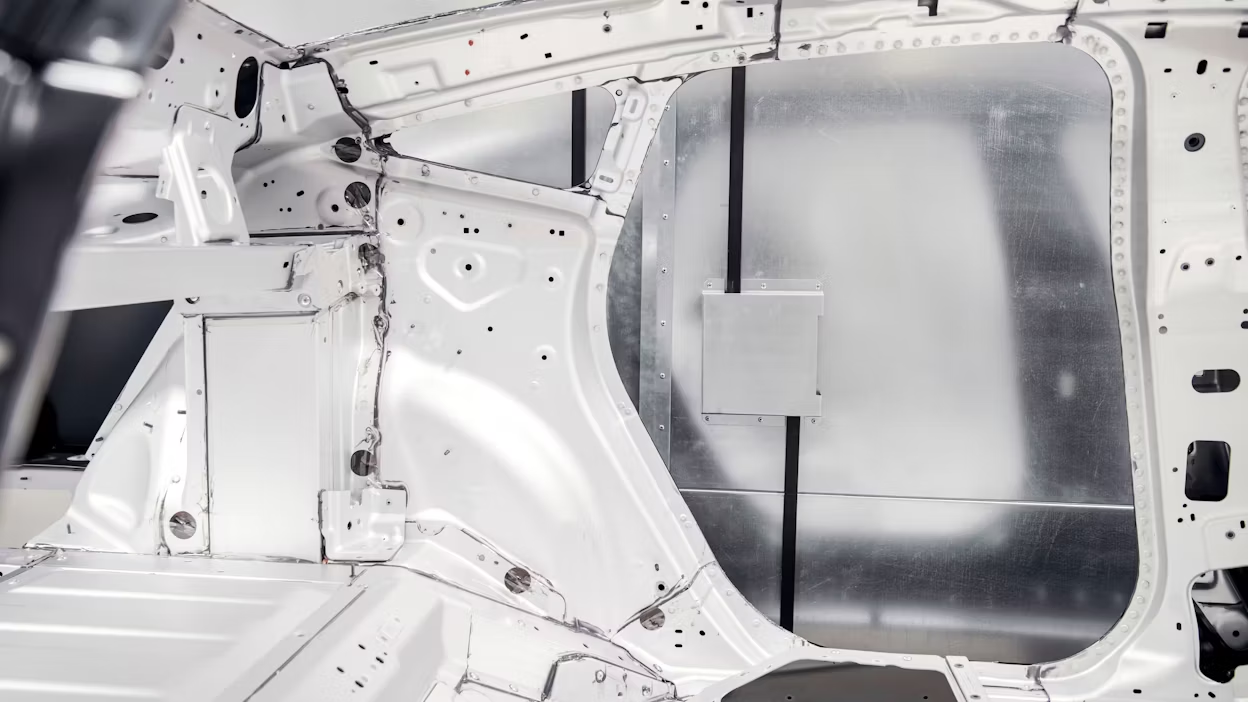

Bonded aluminium unibody technology does away with the mixed metal structures and the 3,500-4,000 rivets normally used in traditional manufacturing, making use of adhesive and oven curing instead. While boasting some serious advantages, it has previously proven difficult for mass production. Both labour-intensive and challenging to scale up without sacrificing quality, bonded aluminium has been restricted to the rarefied air of low-volume performance cars. That is, until the Polestar UK R&D team developed a new method, applying their combined experience from the worlds of Formula 1 and bespoke sports cars to create a process which develops both body and platform in unison.

This combined Polestar 5 platform and body is predicted to weigh less than cars from smaller segments, increasing range and responsiveness while maintaining the highest safety standards. Additionally, this innovation allows for a high degree of design flexibility, as adjustments for factors like different wheelbases can be achieved with comparative ease.

01/04

This is Polestar’s first in-house platform, developed to the same exacting standards as everything else Polestar. This enables the creation of a production car (Polestar 5) that is as close as possible to the concept car (Polestar Precept) that inspired it.

“We knew we wanted this car to be lightweight, we knew we wanted high quality and we knew we wanted it quickly,” says Pete Allen, Head of Polestar UK R&D. “This architecture delivers outstanding dynamic and safety attributes, with low investment technology applicable to high production volumes.”

Those who have been watching “Precept: From Concept to Car” are well aware that the bonded aluminium unibody of Polestar 5 is one innovation of many. And while aluminium itself may suffer from an unjust reputation as something common, its unique properties, when unlocked with breakthroughs such as these, make it more precious than most.