Polestar x Cyclic Materials: an attractive partnership

A partnership between two organizations can be likened to the attraction between two magnets. Just as opposite poles attract, organizations with different skills are drawn together to achieve common objectives. That’s why we’ve signed a memorandum of understanding with North American start-up, Cyclic Materials, which specializes in the recycling of magnets.

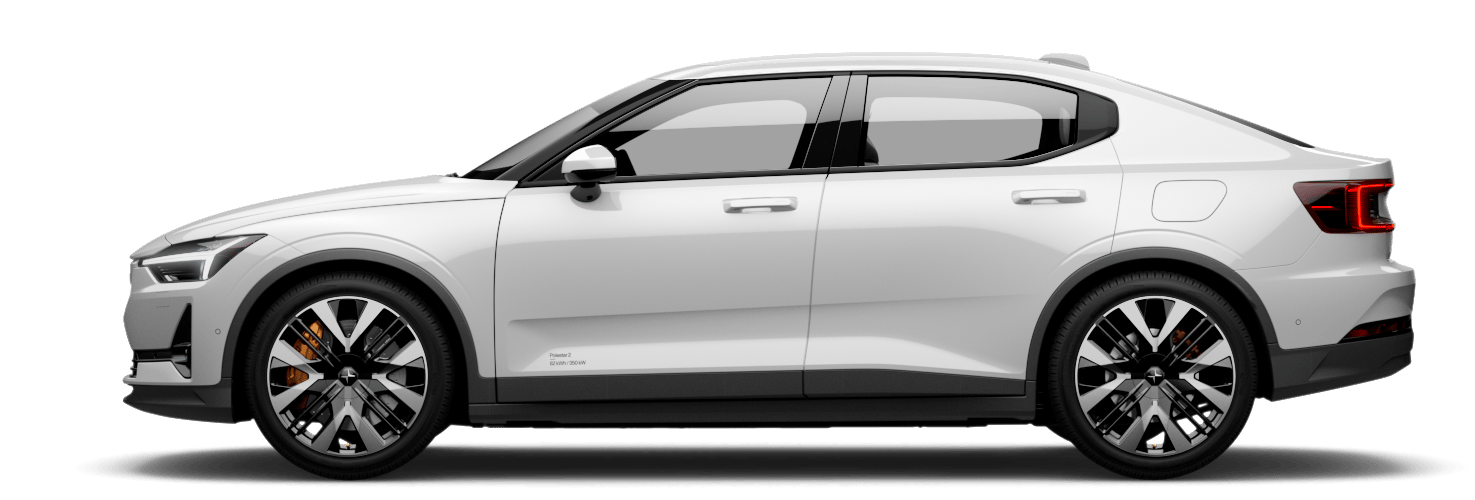

As part of our circularity strategy, we’ve mapped the Polestar 2 for circularity hotspots to identify areas for improvement. We found that electric motors, containing valuable rare earth elements (REEs) like neodymium and dysprosium, had the second-highest raw material footprint, after the car batteries. These elements are crucial to motor function, but their mining and refinement can often introduce environmental risks, such as leakage of toxic effluents that can harm local ecosystems.

In order to combat this problem, we have signed a memorandum of understanding (MoU) with Cyclic Materials to create closed-loop recycling pathways for REEs. The MoU will see the development of recycled magnets for use in Polestar cars, as well as explore ways to efficiently recycle existing magnets. This means that, rather than mining for new raw materials, the company would be able to recycle the REEs from old motors and use them again in new vehicles. By doing so, not only will we reduce our own demand for mining, but also help prevent the loss of biodiversity that can result from the extraction of these elements. Simply put, we want to break new ground without literally breaking ground.

The partnership came to fruition when our Circularity Lead, Sander Jahilo, sparked a dialogue with Patrick Nee, VP of Strategic Partnerships at Cyclic Materials. "The first time I met Sander, he immediately grasped our vision and was eager to move forward with the partnership. The enthusiasm of Polestar has been a major factor in making this happen", Nee says.

Ahmad Ghahreman, CEO of Cyclic Materials, says, “Polestar approached us with a vision of using 100% recycled materials in its electric traction motors and ensuring that all its cars are recycled at the end of their life. Polestar is a leader in circular lifecycle management of their vehicles, and Cyclic Materials is proud to have them as partners in building a circular supply chain for rare earth elements.”

Biodiversity is the lifeblood of our planet. From the air we breathe to the food we eat, biodiversity plays a crucial role in maintaining the health and productivity of ecosystems. The United Nations Biodiversity Conference, or COP15, is an important forum for discussing ways to conserve and sustainably use biodiversity – and for making decisions to help protect and enhance the natural world. This year's conference, held in Montreal, is bringing together representatives from countries around the globe to raise awareness and develop policies that support the conservation and sustainable use of biodiversity. The automotive sector has a crucial role to play in this effort. By investing in technologies that reduce our impact on the environment, we can help to protect and preserve the diversity of life on Earth for future generations.

“To become a circular company, we need to look at where we have the biggest impact – and magnets are among the least circular materials out there”, says Sander Jahilo, Circularity Lead at Polestar. “Cyclic Materials are unique in that they are tapping into materials which have previously been overlooked in the recycling industry due to technical limitations. By partnering with them, we will have a shot at closing the loop on magnets to take a big step towards lowering the raw material footprint of our cars".